NASA assembles spacecraft hardware such as orbiters, landers and rovers in cleanrooms. The cleanroom environment controls the amount of particulate, molecular and biological contamination to specific requirements. So, how is spacecraft hardware built and kept biologically clean?

The cleanroom environment itself and the gowning requirements play a significant role in keeping spacecraft surfaces clean. But merely building the hardware in an International Organization for Standardization (ISO)-class cleanroom doesn’t automatically mean the hardware will remain clean. Other processes must be in place to ensure the hardware is built and maintained biologically clean.

The cleanroom environment minimizes the biological recontamination potential through air filtration and handling, frequent cleaning of surfaces in the cleanroom, and controlling personnel activities. Many of the activities to contain particles in the cleanroom environment also manage biologicals. But there are other requirements and activities used during build and test in the cleanroom that help meet and maintain strict planetary protection requirements. To understand cleanroom processes, the following definitions are important:

- Bioreduction: Removal or destruction of living organisms to some lower population but not necessarily to zero.

- Clean Assembly: Practices that minimize contamination from particulates, dust, airborne organisms or vaporized particles.

- Bioburden: The amount of spore-forming bacteria on a spacecraft (See “What Are Spores?” for more information).

- Cross Contamination: Spores or other bacteria unintentionally transfer between objects, such as the transfer from a tool to the spacecraft surface.

- Assay: Sampling flight hardware to determine the bioburden on a specific surface area. NASA approves the assay procedures used.

- Ground Support Equipment: Equipment (such as cables, tools, computers, etc.), also known as GSE, that does not fly.

- Final Encapsulation: The activity associated with closing up the spacecraft to insert it into the launch vehicle (fairings) and staged for launch.

Planetary Protection requires clean spacecraft hardware assembly practices and prevents recontamination of the spacecraft up until launch. Planetary Protection assembly requires cleaning procedures at “last access” or before the final installation of hardware on the vehicle, including mated surfaces. When spacecraft hardware parts are joined, the mated surfaces between the joined components are no longer accessible for cleaning. Think about assembling a model airplane and gluing the wings to the airplane fuselage or body. For Planetary Protection purposes, it would be essential to clean both the wing’s surface and the plane’s body surface before gluing them together. The mated surfaces cannot be accessed and become “unavailable” after gluing. Planetary Protection requires that mated surfaces meet a required and verified level of biological cleanliness. The level is verified by sampling the surfaces with swabs or wipes and assaying for spores. All areas of the spacecraft hardware, those that are mated and those that are accessible, need to be maintained and routinely cleaned to meet planetary protection bioburden requirements.

Assembly teams clean the old-fashioned way for the most part — they wipe the hardware with a cleanroom wipe and isopropyl alcohol. Isopropyl alcohol does not destroy bacterial spores in general, so they have to be removed by the mechanical action of physical cleaning. Workers do not use detergents in the cleanroom because most of them are ineffective against spores unless they specifically contain a sporicide. More importantly, the cleaning solvent must be compatible with spacecraft hardware to prevent any damage. The approved cleaning solvent is a mixture of 70% Isopropyl Alcohol and 30% distilled water. Hardware is wiped clean before final assembly and installation. Workers routinely wipe down flight hardware surfaces that remain accessible to maintain cleanliness.

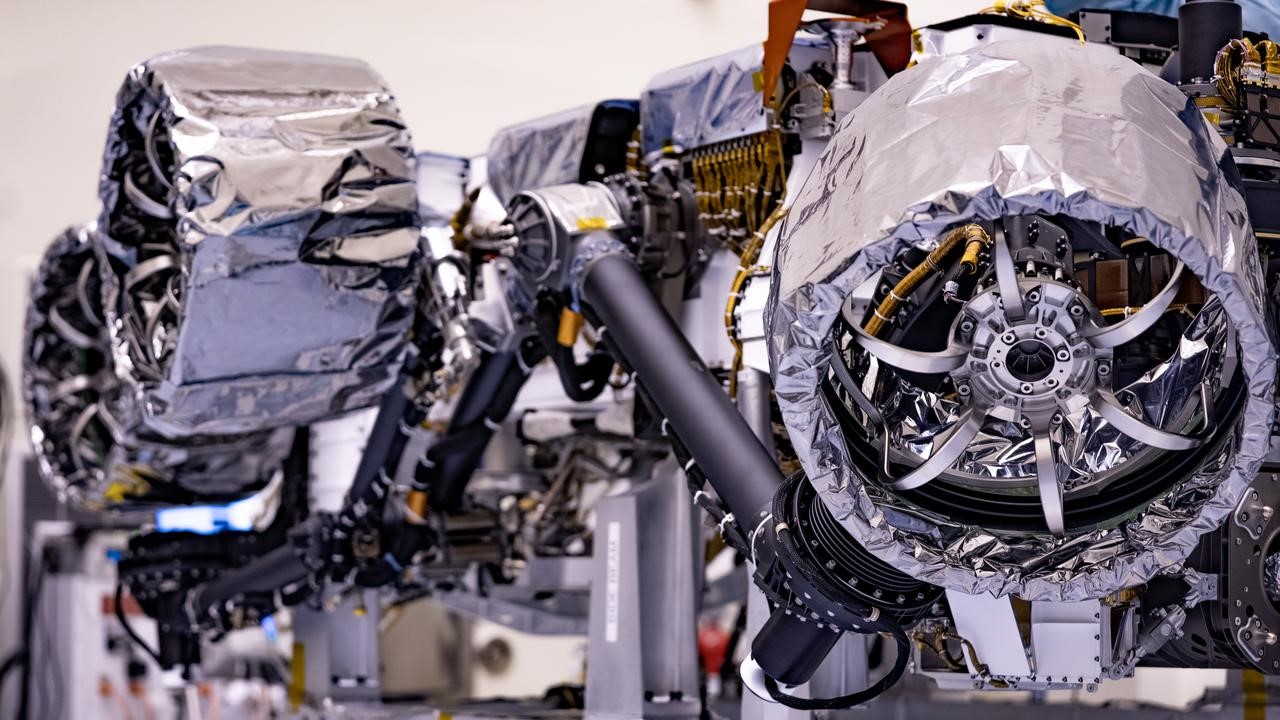

Wiping down hardware is part of the strategy to limit the number of Earth microbes going to the red planet for NASA's Mars 2020 Perseverance mission. This cleaning takes place in the Spacecraft Assembly Facility clean room at NASA's Jet Propulsion Laboratory in Southern California.

Besides cleaning the hardware surfaces, it’s necessary to routinely clean work areas to avoid contamination transfer to hardware. Proper gowning and glove cleaning are required at all times when working with flight hardware.

Maintaining the cleanliness of the spacecraft hardware is a top priority, and all of these activities work toward satisfying planetary protection requirements. Spacecraft hardware is protected with special clean covers or enclosures when direct access by personnel is not needed. Covering could range from a clean cover over the entire spacecraft or clean storage bags and bins for parts that have yet to be installed on the spacecraft.

The Mars 2020 rover undergoes processing inside the Payload Hazardous Servicing Facility at NASA Kennedy Space Center in Florida, on Feb. 13, 2020. The spacecraft was flown to Kennedy from California aboard a C-17 aircraft on Feb. 12. Note the rover is covered to prevent environmental cross-contamination.

There are protection measures on the installed spacecraft hardware as well. “Remove before flight” covers serve multiple purposes; they protect the hardware from accidental contact or damage and protect against biological contamination. The Mars Perseverance rover flight wheel treads, which were covered during assembly to prevent biological contamination, are a good example.

Mars Perseverance Rover wheel covers (remove before flight).

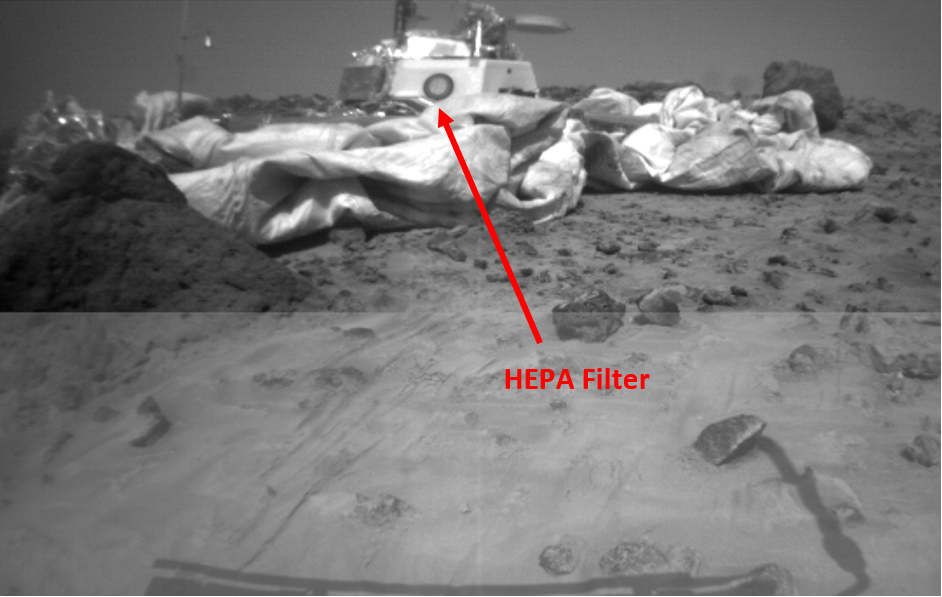

High-Efficiency Particulate Air (HEPA) filters isolate closed volumes that by design can’t be cleaned. Usually, the spacecraft hardware vents gases outward or via positive pressure. The HEPA filter protects adjacent hardware from contamination during the mission. The filter “captures” tiny particles and prevents them from dispersing to other spacecraft areas or to the planetary surface.

Mars Pathfinder photo on Mars taken by Sojourner camera, showing the Integrated Subsystem Assembly HEPA filter

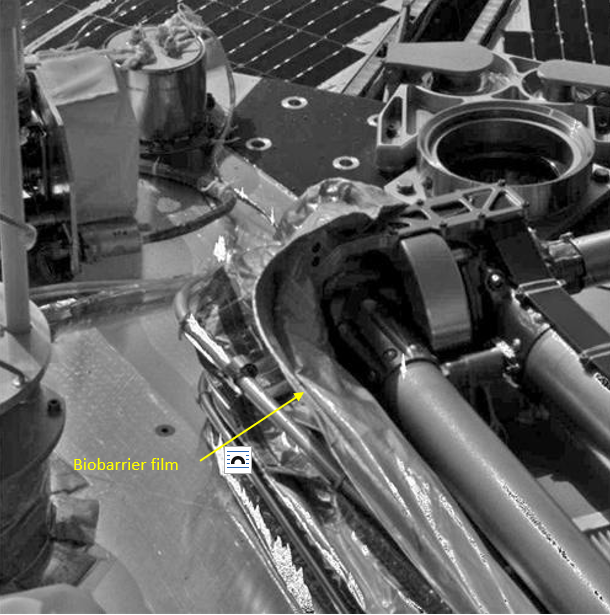

Other barriers against recontamination included biobarriers such as the one deployed on the Mars Phoenix robotic arm. This biobarrier covered the arm to ensure that it remained very clean until deployment. Once Phoenix landed on Mars and was ready to initiate the arm, the protective bio-barrier mechanically opened so that arm could begin operations.

This image from NASA Phoenix Mars Lander Stereo Surface Imager taken on Sol 3. It shows the arm and protective covering called the biobarrier. The biobarrier has opened to allow the robotic arm to deploy.

Avoiding flight hardware contamination takes considerable effort and teamwork in the cleanroom. Successful implementation of Planetary Protection procedures is everyone’s responsibility.

Artist view of the stowed robotic arm on top of Phoenix’s instrument deck