Ground Support Equipment (GSE) is critical to spacecraft build. The equipment can be quite large, including hardware rotation fixtures, cranes, hardware used in specialized lifts and moves, shipping crates, and tall Ballymores and ladders. This type of GSE is complex and extremely large. GSE also includes electrical cables, tools, vacuum hoses, computers, phones, tables, benches, chairs and any other non-flight equipment used to support the assembly activities.

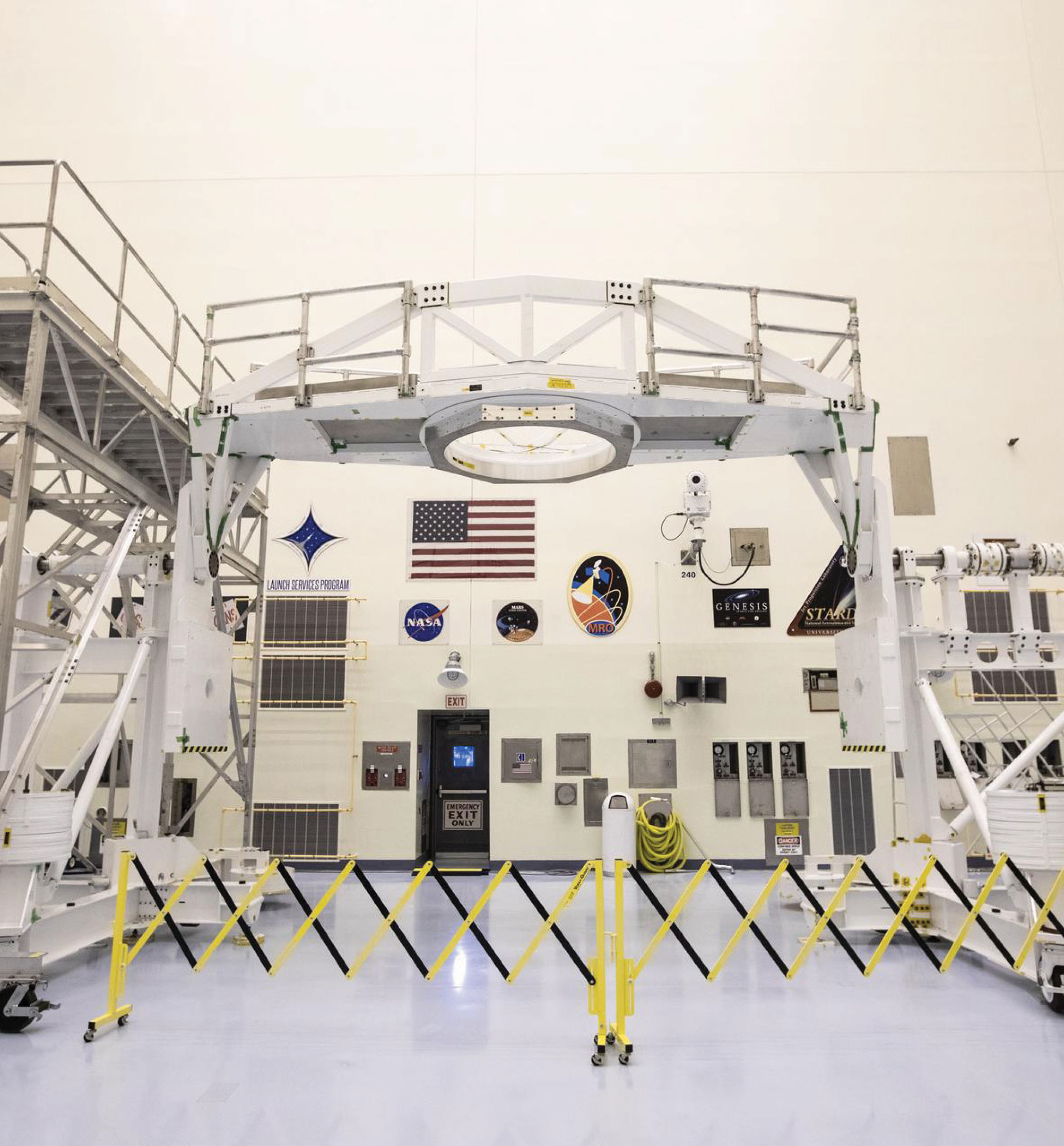

This image shows major components of NASA’s Mars 2020 mission in the High Bay 1 cleanroom in the Jet Propulsion Laboratory’s Spacecraft Assembly Facility. The spacecraft is in the center of the photo. Note all of the GSE in the area to support assembly activities.

Good cleanroom practices are required for these items, including multiple cleaning requirements and GSE bioassays to make sure they are clean before using them in the hardware’s vicinity. Most GSE is cleaned and assayed before it enters the clean room.

Large equipment provides unique cleaning challenges. A good example is the Spacecraft Assembly and Rotation Fixture (SCARF) used for the Perseverance mission. The hardware is used to lift, rotate and reposition the hardware for various operational activities. The SCARF is very large so that it can hold hardware and also has high Ballymore ladders that are used by personnel to access the hardware. Because of the close proximity and direct contact with the hardware, the SCARF is routinely cleaned and assayed.

The SCARF that will be used to process the Mars 2020 rover is photographed inside the Payload Hazardous Servicing Facility at NASA’s Kennedy Space Center in Florida, on Nov. 22, 2019. Attached to the SCARF is an access stand that will allow personnel to reach the spacecraft when it’s held above ground level.

Crane fixtures used to lift and move the hardware also present a cross contamination concern. With hardware of this size, cross contamination is controlled by the diligence of the personnel working in the cleanroom, which includes clean gloving, wipe downs of the lift hardware and if needed covering the hardware during lift operations.

During assembly, the spacecraft will be moved or shipped to different facilities to undergo environmental testing, integrate additional hardware or to prepare for launch. Moving the spacecraft requires a clean moving or shipping container. The container must be fabricated with materials that can be cleaned and wiped down.

Before bringing a container into a cleanroom and placing the spacecraft or hardware into it, its internal and external surfaces are cleaned and assayed to determine their cleanliness level. This process prevents the container surfaces from cross-contaminating the spacecraft surfaces. Personnel also bag the spacecraft before putting it into a shipping container to protect it further.

Personnel supporting NASA’s InSight mission to Mars load the crated InSight spacecraft into a C-17 cargo aircraft at Buckley Air Force Base, Denver, Colorado, for shipment to Vandenberg Air Force Base, California. The spacecraft, built in Colorado by Lockheed Martin Space Systems, was shipped Dec. 16, 2015, in preparation for launch from Vandenberg in March 2016.

Inside the Astrotech processing facility at Vandenberg Air Force Base in California, NASA’s IInSight spacecraft has been removed from its shipping container and is being moved for removal of protective wrapping.

Other GSE includes hand tools, which are routinely wiped and should not be stored or set on the floor. Tools are stored in clean containers or toolboxes when not in use. Large equipment such as vacuum hoses, electric cables and other large support equipment is not stored on the floor and exhaust from items such as power tools, pumps and blowers is mitigated via the use of HEPA filters or other means of capturing exhaust flows. Tools that shed particulates are avoided (steel wool, bristle brushes).

All day, every day, assembly technician’s work in this stringent environment to make sure that flight hardware meets planetary requirements. It takes discipline and teamwork to maintain the required environment and to meet assembly and launch schedules.

Mars 2020 Lift Activities in Payload Hazardous Servicing Facility