Up Lifting the Space Mission: Strand Jacks and Hydraulic Jacking Systems

Basic Strand Jack Operations

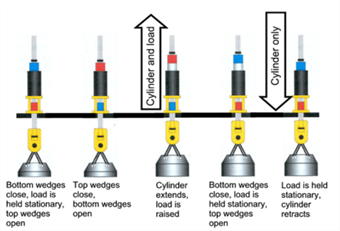

The strand jack is composed of a hollow hydraulic cylinder with a set of cables (typically steel) passing through the open center. Each cable passes through two wedges mounted on either end of the cylinder. The cables are referred to as “strands.”

The strand jack lifting system utilizes a repeating sequence of locking, pulling and unlocking mechanisms. When the bottom wedges are closed, the load is held stationary.

Then, the top wedges are closed, and the bottom wedges are opened, to allow the cylinder to extend, raising the load. The load is then held stationary again when the bottom wedges close and the top wedges open to allow the cylinder to contract.

NASA personnel at Marshall Space Flight Center are preparing for a big lift in support of the Artemis Program.

In the coming months, NASA intends to use four strand jacks in unison to lower the test stand’s crosshead, which weighs 1.25 million pounds, or 625 tons, onto Test Stand 4693 with the Exploration Upper Stage (EUS) test article underneath.

In the coming months, NASA intends to use four strand jacks in unison to lower the test stand’s crosshead, which weighs 1.25 million pounds, or 625 tons, onto Test Stand 4693 with the Exploration Upper Stage (EUS) test article underneath.

Strand jacks allow NASA to safely and efficiently reconfigure structural test stands to support development testing of the EUS for Block 1B and Block 2 designs of the Space Launch System.

In industry, they are widely used to erect bridges, fabricate buildings and lift other large structures when the use of conventional cranes is either impractical or too expensive.

“Strand jacks are cylindrical hydraulic jacks used to lift very heavy loads,” explained Andy Norris, Marshall Lifting Device and Equipment (LDE) manager. “Thousands of tons can be lifted when multiple strand jacks are combined.”

For this operation, each strand jack has a 400,000 pound, or 200-ton, capacity. And when it comes to completing complex lifts at NASA, strand jacks offer clear advantages, beyond their impressive weight capacities.

“Strand jacking allows large sections of pre-built construction materials to be lifted and placed with pin-point precision,” said Clifton Arnold, Program Executive-LDE, Office of Safety and Mission Assurance. “The alternative would be using multiple cranes to fabricate in-place, which can present an array of safety issues.”

Additionally, strand jacks have a small footprint and allow a single operator to operate multiple jacks using computerized controls.

For more information on this lift, contact Norris or Arnold.