Characterization of the Wide Field Planetary Camera-2 Radiator’s Cored Impact Features at NASA JSC

This article by K. Ross and P. Anz-Meador originally appeared in Orbital Debris Quarterly News, Volume 17, Issue 3, July 2013.

Hubble Space Telescope’s Wide Field Planetary Camera‑2 (WFPC‑2) was returned to Earth during the STS‑125 servicing mission in 2009, after almost 16 years in low Earth orbit. The radiator of WFPC‑2 collected numerous impact craters due to exposure to the micrometeoroid and orbital debris (MMOD) environment (ODQN, January 2010, pp. 3-4). These impact features were cored from the radiator (ODQN, July 2012, pp. 4‑6) to permit direct examination of the impacted surface and investigation to identify the impactor. Hypervelocity impacts by MMOD are energetic events, with fragmentation, melting, and vaporization of parts of both the impactor and target materials. Thus, residues of the impactor may be rare, fine-grained, and/or dissolved or engulfed in impact-melted target materials.

Four hundred and eighty WFPC‑2 cores of impact features have been examined using scanning electron microscopy methods. Approximately half of these samples have been examined in England, at the Natural History Museum and at the University of Surrey’s Ion Beam Centre. The NASA Orbital Debris Program Office is investigating the remaining samples using the Astromaterials Research and Exploration Science Directorate lab facility at the Johnson Space Center. Electron microscopy permits high magnification imaging of the impact features, and chemical analysis of target and residues of impactor materials. Bombardment of materials by energetic electrons induces the emission of x‑rays, and the x‑ray spectrum contains peaks that represent elements abundant in the target region. Each element in the periodic table produces a set of x‑ray line energies that are characteristic of that element. Thus, collection of x‑ray spectra permits the identification of elements present in the sample, and x‑ray line intensities are a function of the abundances of the elements.

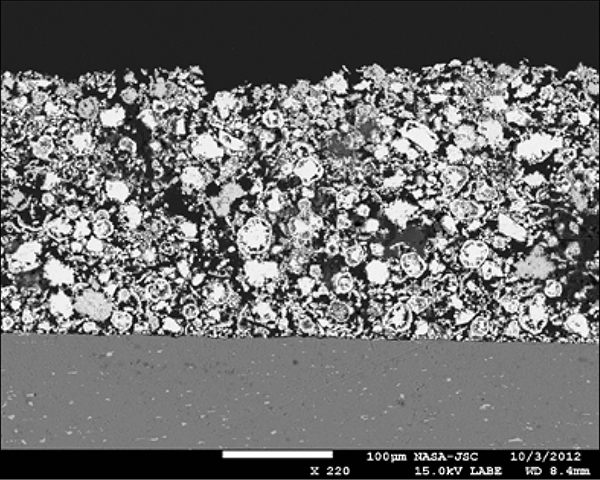

Figure 1 shows a cross section through a blank (non‑impacted) core. The complex character of the “target” material is shown, with an ~200 micron‑thick layer of paint overlying Al‑metal. The paint consists of Zinc orthotitanate (Zn2TiO4) pigment and the PS7 potassium silicate binder. The paint layer is made up of sub‑rounded paint particles and is very porous. The underlying Al‑6061 alloy layer encompasses many fine-grained inclusions of Fe-Mn-Cr-Si, as well as less abundant Mg‑Si‑O‑bearing particles. Given the chemical complexity of the target material, impacts that penetrate to the Al layer are particularly difficult to assign to an impactor type because of the additional elements that could be in impact melts of the target.

Figure 1. Backscattered electron image of a cross-section of an un-impacted core, showing the overlying, porous paint layer, and the underlying Al-metal substrate, with abundant Fe-rich inclusions.

WFPC‑2 impact features were examined using two scanning electron microscopes. A JEOL 7600F scanning electron microscope (SEM), equipped with a ThermoScientific SD (silicon drift) x‑ray detector, as well as a JEOL JSM‑5910LV SEM, equipped with a ultrathin‑window Si(Li) x‑ray detector, were used to examine, image, and obtain chemical analyses from the cored impact features. Cores were carbon coated to ensure electrical conductivity. Secondary and backscattered electron images of craters were collected to permit measurement of feature sizes, and to search for unusual compositions. Regions within and near craters were searched in backscattered electron imaging (BSE) mode (which highlighted compositional variations). Phases that were notably different in brightness in BSE mode were characterized for chemistry by collection of x‑ray spectra. The complex character of the impacted surface, with Zn‑orthotitanate and potassium silicate constituents, as well as substantial porosity, variable volatile element contents, and non‑smooth surface topography, resulted in very complex backscattered response.

The best location for searching for impactor residues appears to be the impact melts found in the craters. The critical aspect that makes impact melts the best location is that elements found dissolved in the impact melts must have been present when the impact happened. Particles found on the surface might be from the impactor, but could also be contaminate, unrelated to the impactor. Melts derived from the painted surface always contain Zn, Ti, K, Si and O. We also note that some source of Al is widely present in the paint, and Al is very frequently found as a minor component in melts formed from paint. We have observed Al‑rich particles within pore spaces in the paint layer distal from any impact. Thus, the impact melts are chemically complex, and any impactors that consisted of Zn-, Ti-, or Al‑bearing materials are unlikely to be recognized, because all of these elements are already present in the target.

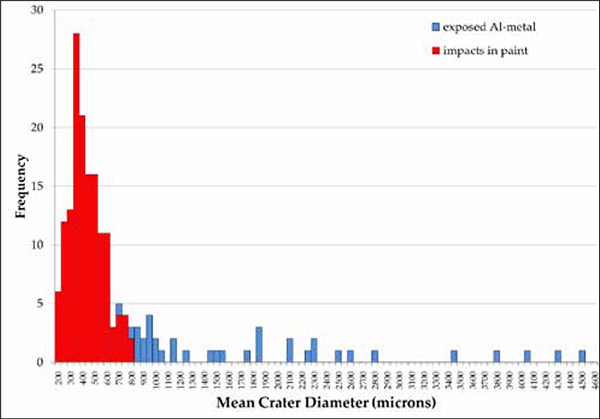

Observations of the sizes of impact features are presented in Figure 2. The smallest impacts were not cored, so the distribution of impact sizes falls off at small diameters (<300 microns). At larger sizes, the frequency of impacts declines exponentially. Figure 3 shows secondary electron images of examples for both types of craters (those that penetrated only paint, and those that penetrated both paint and underlying metal substrate). Damage equations that relate impact feature size to impactor size, density, and velocity will need to account for the stratified nature of the target, the differing material properties of the two layers, and the weak nature of the interface between the two layers.

Figure 2. Histogram of the measured mean diameters of impact features.

Figure 3. Secondary electron images of impact features WFPC2-81 (left) and WFPC2-34 (right). The impact crater at the top penetrated the paint layer only. The larger impact feature at the bottom penetrated to and exposed the underlying Al alloy substrate. A sub-crater is visible in the metal, showing that the impactor energy penetrated to and damaged the metal substrate, as well as removing a large volume of paint.

The distinctive character of impacts into paint versus more energetic impacts that exposed underlying metal is shown in Figure 3. Impacts that bottomed out in the paint layer have bowl- or cone‑shaped floors, and are generally lined with abundant frothy impact melts. Impacts that reached the Al‑alloy layer often expose large, flat‑bottomed floors, with sub‑craters formed in the metal. Impact melts that are rich in Al in the floor of these craters are not frothy, because the Al alloy was not rich in volatiles so no out‑gassing occurred from the impact-melted Al. The detachment and excavation of paint from these deeper craters often carried away impact melted paint, perhaps removing the best target material for this study.

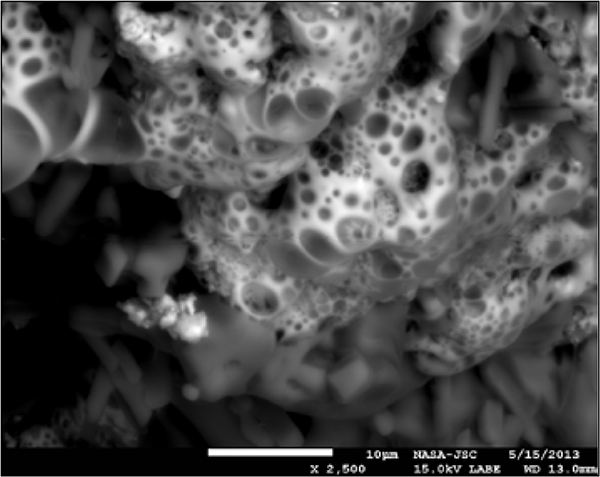

Figure 4 shows frothy textures in impact melt of paint in one impact feature. The texture of melted paint is readily distinguishable from unmelted paint. The search for rare impactor residues requires sampling the paint composition, often in many locations, before any likely impactor residues are located. Impactor residues are dissolved in and strongly diluted by the more abundant elements that reside in the paint.

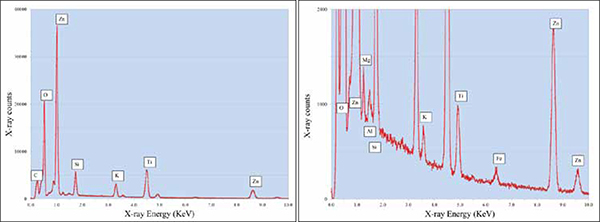

Figure 5 shows an x‑ray spectrum from the impact-melted paint shown in Figure 4. The elemental composition of the impact melt is dominated by Zn, Ti, Si, K and O, with minor Al, indicating that this impact melt is made up dominantly of elements derived from the paint layer. The expanded view of the spectrum shows that Mg and Fe are also constituents of the impact melt. This impact feature did not penetrate to the underlying metal substrate, so that it appears that the only available source for the Mg and Fe is a micrometeoroid impactor. We note that Si is a major constituent of the paint. While it is very likely that Mg- and Fe‑bearing micrometeoroid impactors would be accompanied by Si, we cannot use Si in the paint as an indicator of any impactor type, as it is already present.

This study has partitioned the impacting population into its micrometeoroid and orbital debris components; that portion of the total thus identified can be used to characterize the overall population statistics among those features not identifiable as being micrometeoroids or orbital debris. Damage equations for painted surfaces and the time history of the WFPC‑2 orientation are being developed and, coupled with the population identified by this work, shall be used in near- and long-term models of the orbital debris environment in low Earth orbit. A subsequent article will describe the overall results of the examination of WFPC-2.

Figure 4. Close-up backscattered electron image of frothy, melted paint in impact core WFPC2-68. The impact-melted paint layer typically contains abundant bubbles formed by outgassing of volatile elements that resided in the paint before impact.

Figure 5. Example x-ray spectrum of melted paint from WFPC2-68. Panel at right shows a vertically expanded view of the same spectrum, with Mg and Fe in melt. These elements are likely indicators of a micrometeoroid impactor.