Goddard Develops Software Tools to Improve Mission Reliability

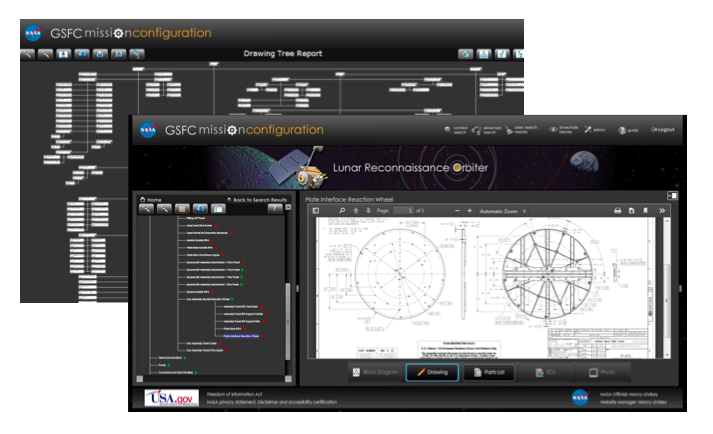

Mission Configuration Interactive Drawing Tree and Data Displays

Examples from the Lunar Reconnaissance Orbiter Mission

Goddard Space Flight Center (GSFC) has developed two integrated web-based software tools — Mission Configuration and the Failure Interrogation and Archiving Tool (FIAT) — to improve failure rate predictions for the center’s missions. These tools, working in conjunction, will improve reliability for current and future missions.

Mission Configuration

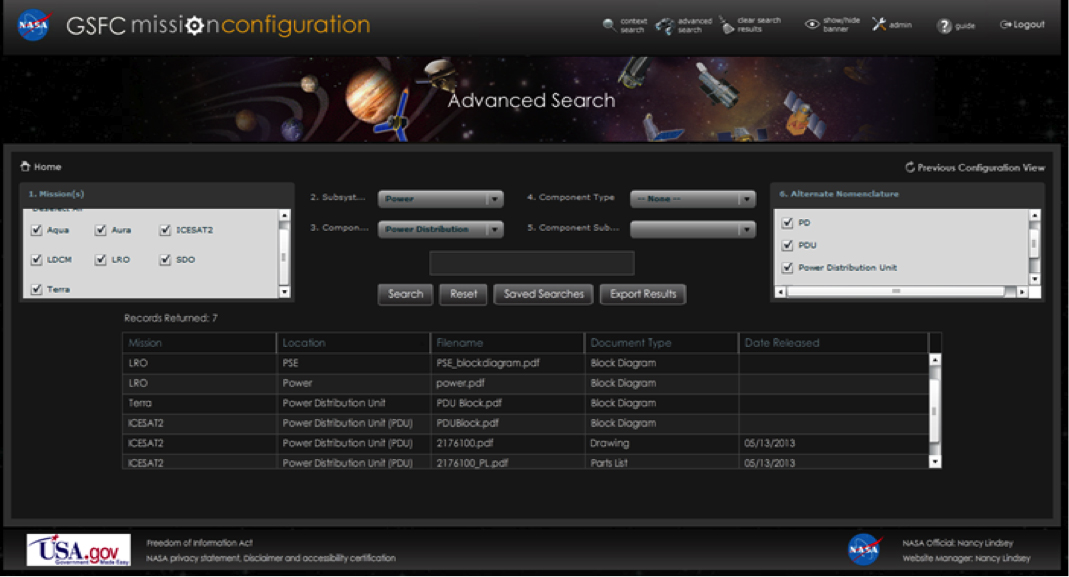

The GSFC Mission Configuration is a web-based perpetual repository for GSFC mission data, including functional block diagrams, drawings, engineering change orders, parts lists and item close-out photos. Mission Configuration is searchable and stores data for each mission in tree structures that allow the user to view how the parts are related and connected, as well as drill down within a mission or search across missions using project or standard taxonomy, part numbers, keywords, configuration descriptions, or any type of configuration-related data.

According to GSFC Senior Reliability Manager Nancy Lindsey, Mission Configuration was created to fulfill the center’s need to “more easily find out what we are flying and what we are testing.”

Mission Configuration Across Mission Searching

The previous process, which involved accessing data in project-specific configuration management systems or archived configuration information on CDs stored at a remote facility, made it nearly impossible to reference configuration data for existing projects without considerable effort and special permissions. There was also no way to see the relationship between the diagrams and the parts, said Lindsey. Even if a reliability engineer was able to locate a diagram for a particular part, the engineer would not understand its hierarchical context — what parent it belonged to and any children it had, crucial information for reliability analysis — without contacting project personnel directly.

Mission Configuration has greatly improved this process with streamlined data gathering. The software also acts as a kind of “Rosetta Stone,” to relate and/or connect with configuration-associated data in other systems, such as the Spacecraft Orbital Anomaly Reporting System (SOARS) or Project or Safety and Mission Assurance risk databases. This allows the reliability engineer to focus on the enhanced reliability analysis versus data gathering.

In addition to assisting reliability engineers, Mission Configuration can be a resource used by proposal teams, design engineers, quality assurance personnel, systems safety personnel, integration and test teams, operators, and anomaly investigators, or for systems engineering activities. Users can easily access archived design information to support initial architecture design or proposal development or to develop an understanding of the system.

“It can be used all the way through a mission’s process, from proposal and through launch for quality or safety or risk assessments, as well as facilitate knowledge and lesson learned sharing to avoid increased costs or missteps,” said Lindsey.

GSFC started working on Mission Configuration in 2009. The software is now operational for GSFC use, and could be a beneficial tool for the whole agency in the future.

Failure Interrogation and Archiving Tool (FIAT)

FIAT is a web-based tool that uses Bayesian analysis to provide more accurate reliability predictions for risk assessment. The tool fulfills the requirement from NASA Policy Directive 8720.1 to share experience data in support of current, follow-on, and new programs and projects.

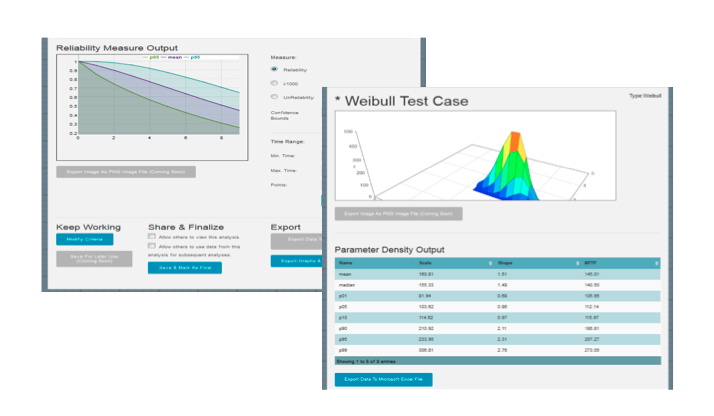

FIAT, by design, uses the Mission Configuration archived data context or a user-specified configuration item to develop failure rate estimates based on GSFC heritage on-orbit performance and controls. It is a web-based analysis structure that can be used to update previously very conservative predictions (e.g., MIL-HDBK-217), of performance success to those that reflect actual on-orbit history and the impacts of NASA processes and controls by the use of Bayesian analysis. An analyst using FIAT is able to integrate on-orbit anomalies (from SOARS or other incident reporting repositories) and success data to develop homogeneous, non-homogenous, an expert opinion or Weibull failure distributions (with multiple selectable options) that can be modified, viewed and shared as a GSFC prediction of performance. The results can be viewed in interactive graphs, including 3-D graphs, which are exportable and project useable.

“FIAT provides more accurate and performance-based failure rates, which allows better decision making for reliability, redundancy, testing, failure or extension analysis,” said Lindsey.

Example of FIAT Output & 3-D Graph: 10-Data-Point Hypothetical Test Case With Start and End Time

Lindsey worked closely with Nancy Rackley, B-Line Express program manager, on architecting the tool, but attributes the functionality and successful development of the tool to the expert B-Line Express FIAT development team. B-Line Express not only utilized its own internal expertise but also the expertise of Prediction Technologies Inc (PTI) and a flexible and interactive environment to achieve rapid prototyping and integration of the PTI R-DAT computational engine to create FIAT. This environment and the agile program management of Rackley and Lindsey allowed for easy revision and migration of the new tool from development to production in a single calendar year, said Lindsey.

FIAT is live, but is going through validation and verification to ensure that it performs as expected and produces accurate and predictable results before it becomes operational.

Moving Forward

Lindsey hopes that Mission Configuration will expand in the future to include everything currently being flown and about to fly at NASA, and to increase the size of the perpetual archive.

“The further dream is to engage other centers in the Mission Configuration and FIAT process to get the experience data and create better profiles for new failure rates for components or parts,” said Lindsey. “Mission Configuration could share lessons learned between different partners, so that as we partner together, we are starting from the same sheet of music so to speak, leveraging what was done by our agency engineering predecessors.”